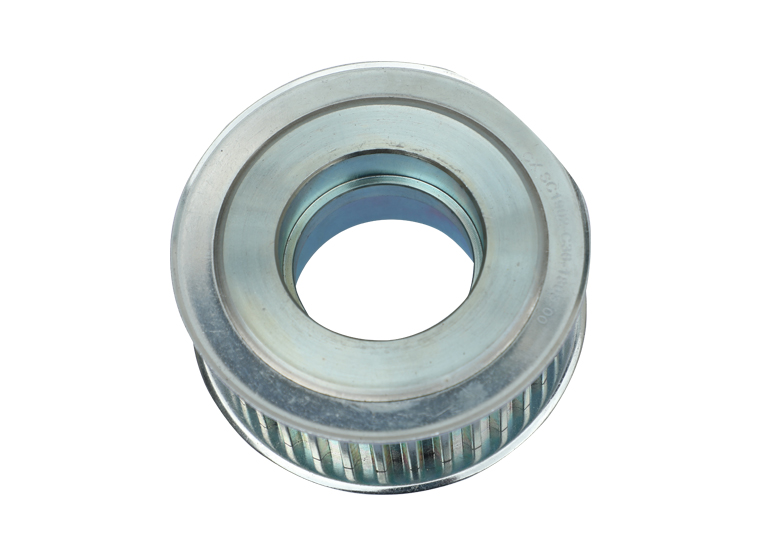

product

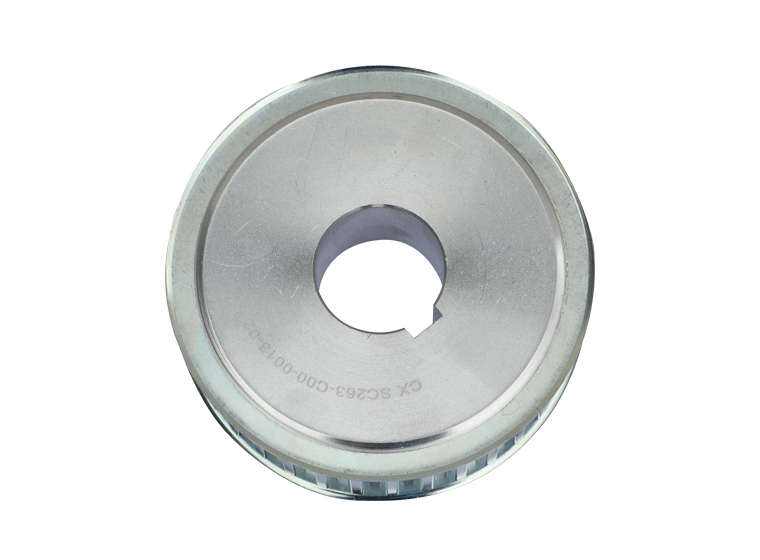

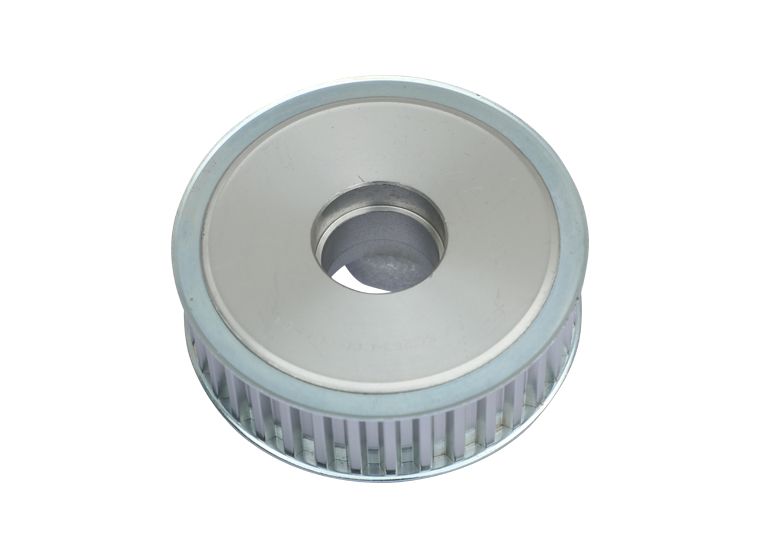

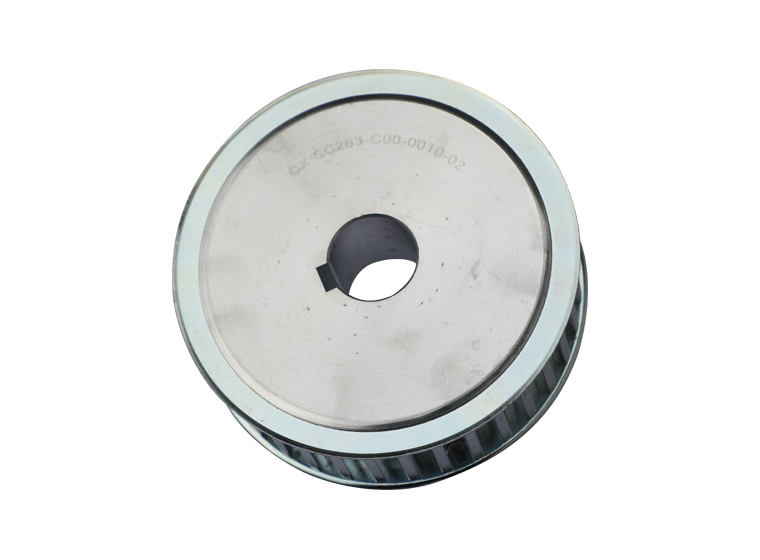

product

Synchronous pulley:Widely used in mechanical, textile, printing, tobacco, chemical, light industry, metallurgy, mining, instrumentation, petroleum, automotive and other industries. Our company can design and manufacture synchronous pulleys for various purposes for users, with reasonable prices and timely delivery. We welcome cooperation.

Multi wedge pulley:Multi wedge belt transmission is a comprehensive transmission of V-belts and flat belts, with advantages such as high transmission power, good twisting performance, long service life, low energy loss, and low elongation. It will gradually replace V-belts, flat belts, and other fields.

01

Synchronous Pulley

02

Photovoltaic pulley

Type of Basic Structure of Synchronous Pulley

P=Pitch is the distance between the axes of two adjacent teeth irespecive of whether these teeth are on the pulley or the belt provided that measurement is taken on the circum ference of pitch line

Z=Nunber of pulley teeth

Dp=The diameter of the pulley pitch is obtained from fomula Dp=P.Z/π

De=External diameter of pulley De=Dp-2k

Dm=Hubs diameter

d=Bore diameter

W=Tooth width

L=Total lenght incl hubs

Synchronous pulley materials:steel,cast piece,aluminium alloy

1.Pitch tolerance(mm)

| Outside diameter pitch | Tolerance windage | |

| any two close gears | 90°arc | |

| ≤25.40 | 0.03 | 0.05 |

| >25.40-50.80 | 0.03 | 0.08 |

| >50.80-101.60 | 0.03 | 0.10 |

| >101.60-177.80 | 0.03 | 0.13 |

| >177.80-304.80 | 0.03 | 0.15 |

| >304.80-508.00 | 0.03 | 0.18 |

| >508 | 0.03 | 0.20 |

2.Toerance of outside diameter of pulley(mm)

| Outside diameter pitch | Outside diameter |

| ≤25.40 | +0.050 |

| >25.40-50.80 | +0.080 |

| >50.80-101.60 | +0.100 |

| >101.60-177.80 | +0.130 |

| >177.80-304.80 | +0.150 |

| >304.80-508.00 | +0.180 |

3.Allowable bounce of pulley end(mm)

| Ourside Diameter | Allowable Bounce |

| ≤101.60 >101.60-254.00 >254.00 |

0.10 Outer diameter of pulley×0.001 0.25+[(Outer diameter of pulley-254.00)×0.005] |

4.Allwable bounce of pulley warp direction(mm)

| Outside Diameter Pitch | Allowable Bounce |

| ≤203.20 >203.20 |

0.13 0.13+[( Outer diameter of pulley-203.20)×0.005] |

1.Trapezoid tooth Synchronous Belt Symbols Denote Method

Example:

2.T Type Symbols Denote Method

Example:

3.HTD type pulley Symbols Denote Method

Example:

1.Dimension & tolerance of linear type pulley(mm)

| Type | bw | hg | β±1.5° | rb | rt | 2k |

| MXL | 0.84±0.05 | 0.69 | 20 | 0.35 | 0.13 | 0.508 |

| XXL | 1.14±0.05 | 0.84 | 25 | 0.35 | 0.30 | 0.508 |

| XL | 1.32±0.05 | 1.65 | 25 | 0.41 | 0.64 | 0.508 |

| L | 3.05±0.10 | 2.67 | 20 | 1.19 | 1.17 | 0.762 |

| H | 4.19±0.13 | 3.05 | 20 | 1.60 | 1.6 | 1.372 |

| XH | 7.90±1.15 | 7.14 | 20 | 1.98 | 2.39 | 2.794 |

| XXH | 12.17±0.18 | 10.31 | 20 | 3.96 | 3.18 | 3.048 |

2. Dimension of T type pulley (mm)

| P | Type | Type | β Grad |

rb | rt | 2k | ||||||

| SE br |

N br |

SE hg |

N hg |

|||||||||

| ourside diameter | ourside diameter | ourside diameter | mix | ±1.5° | max | ourside diameter | ||||||

| T2.5 | 1.75 | +0.050 | 1.83 | +0.050 | 0.75 | +0.050 | 1 | 25 | 0.2 | 0.3 | +0.050 | 0.6 |

| T5 | 2.96 | +0.050 | 3.32 | +0.050 | 1.25 | +0.050 | 1.95 | 25 | 0.4 | 0.6 | +0.050 | 1 |

| T10 | 6.02 | +0.100 | 6.57 | +0.100 | 2.6 | +0.100 | 3.4 | 25 | 0.6 | 0.8 | +0.100 | 2 |

| T20 | 11.65 | +0.150 | 12.6 | +.0150 | 5.2 | +.0130 | 6 | 25 | 0.8 | 1.2 | +0.100 | 3 |

3.Dimension of HTD type pulley(mm)

| Type | P | hg | R | S | r | angly | 2k |

| 3M | 3 | 1.28 | 0.91 | 1.90 | 0.3 | ≈14° | 0.762 |

| 5M | 5 | 2.16 | 1.56 | 3.25 | 0.48 | ≈14° | 1.14 |

| 8M | 8 | 3.54 | 2.57 | 5.35 | 0.8 | ≈14° | 1.372 |

| 14M | 14 | 6.20 | 4.65 | 9.80 | 1.4 | ≈14° | 2.794 |

| 20M | 20 | 8.60 | 6.84 | 14.80 | 1.4 | ≈14° | 4.30 |

4.Dimension of S type pulley(mm)

| Type | P | hg | R | S | 2k |

| S2M | 2 | 0.76 | 1.325 | 1.30 | 0.508 |

| S3M | 3 | 1.11 | 1.975 | 1.95 | 0.762 |

| S4.5M | 4.5 | 1.59 | 2.98 | 2.93 | 0.762 |

| S5M | 5 | 1.77 | 3.275 | 3.25 | 0.96 |

| S8M | 8 | 2.83 | 5.30 | 5.20 | 1.372 |

| S14M | 14 | 4.95 | 9.28 | 9.10 | 2.794 |

5.Dimesion of AT type pulley(mm)

| Type | Pitch | Tooth angle | Groove width | Tooth heigth | Fillet | Tip | 2k |

| PB | 2β° | s | jg | Radiusr1 | Radiusr2 | ||

| AT3 | 3 | 50±1 | 1.5 | 1.0 | 0.3 | 0.2 | 0.6 |

| AT5 | 5 | 2.7 | 1.10 | 0.86 | 0.40 | 1 | |

| AT10 | 10 | 5.4 | 2.35 | 1.25 | 0.40 | 2 | |

| AT20 | 20 | 10 | 5.00 | 2.50 | 1.75 | 2.96 |

6.Dimension of RPP type pulley(mm)

| Type | Pitch | Groove width | Tooth heigth | 2k |

| PB | s | jg | ||

| P3M | 3 | 2.00 | 1.09 | 0.76 |

| P5M | 5 | 3.32 | 1.81 | 1.14 |

| P8M | 8 | 5.35 | 2.9 | 1.37 |